Project Description

High low temperature alternating climatic chamber is necessary for products temperature testing……

Description

High low temperature alternating climatic chamber is mainly for testing and determining the parameters and performance of electrical, electronic products and materials upon the change of the environment in high-temperature, low-temperature alternating test.It is appropriate for testing material performance, such as resist heat, resist dry and resist cold.

High low temperature alternating climatic chamber capacities ranging from 50 to 1000 liters to accommodate many product sizes. Temperature Range: -70°C to +150°C.We also provide custom temperature chambers to meet individual size and performance needs.

Application

- Electronic parts

- Home appliance

- Auto parts

- Telecommunications

- Aerospace industry

- LED lights

Detailed pictures

TEMI 880 LCD Controller

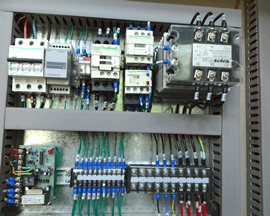

Safety Device

France Tecumseh Compressor

- Working chamber corrosion resistance SUS#304 stainless steel material

- Input mode PT100 Temperature sensor

- 5.7 inch TEMP880 LCD controller,program with 99 groups,999 cycles

- RS232 computer interface and software

- France “Tecumseh” compressor or Hermetic Refrigeration Compressors

- Environment friendly Refrigerant R404A & R23

- Air circulation for uniform airflow within the inner chamber.low noise fans

- Alternating between high temperature and low temperature back and forth

- Door seal adopts silicone rubber material which can avoid aging and hardening in high low temperature conditions.

- 50mm diameter cable port comes standard on the left side of the chamber

- With larger transparent viewing window and lighting inside to observe the test

- Energy efficient, long life span Philip lighting

- Casters for easy moving during installation or relocation

- Adjustable shelves

| Model | JYGDJ-50 | JYGDJ-100 | JYGDJ-150 | JYGDJ-250 |

| Internal Size W*D*H (mm) | 350×320×450 | 500×400×500 | 500×500×600 | 600×500×810 |

| External size W*D*H(mm) | 950×950×1400 | 1050×1030×1750 | 1050×1100×1850 | 1120×1100×2010 |

| Model | JYGDJ-500 | JYGDJ-800 | JYGDJ-1000 | |

| Internal Size W*D*H (mm) | 800×700×900 | 1000×800×1000 | 1000×1000×1000 | |

| External size W*D*H(mm) | 1350×1300×2200 | 1560×1410×2240 | 1560×1610×2240 | |

| Temp.range | Model A :-20°C~+150°C Model B: -40°C~+150°C Model C: -70°C~+150°C | |||

| Temp. fluctuation | ≤±0.5°C | |||

| Temp. uniformity | ≤2°C | |||

| Heating rate | 2~3°C/min | |||

| Cooling rate | 0.7~1°C/min | |||

| Timing | 1S~9999H | |||

| Power Supply | AC220V·50HZ/380V·50HZ | |||

| Heater | Nickel wire heater | |||

| External material | A3 steel plate,surface electrostatic spraying | |||

| Insulation materials | Superfine fiberglass wool / polyurethane foam | |||

| Circulatory system | Temperature low-noise motors, single cycle, plus the long axis, stainless steel multi-leaf type centrifuge fan | |||

| Refrigeration | Unit cooling mode / Dual cooling method (air-cooled),according to size of chamber and specific low temperature | |||

| Standard Configuration | One observe window(Resistant to high and low temperatures hollow toughened glass window, a fluorescent lamp, two layer stainless steel shelves | |||

- 7.5 inch TEMI2700 TFT-LCD Touch Screen Programmable controller,programs with 120 patterns,max 1200 segments,max 999Hour 59Min 59Sec can be set

- Ethernet interface

- SD Memory Card support

- Remote control and remote monitoring possible via intranet or internet

- Additional 50mm or 100mm diameter cable ports

- Germany “Bitzer” refrigeration compressor

- Additional shelves

TEMI2700 Picture