Project Description

3 Zone Thermal Shock Chamber is very necessary for material testing under extremely environmental conditions……

Description

3 Zone Thermal Shock Chamber is used to test the material structure or composite material in a instant by the extremely high temperature and very low temperature continuous environmental which can endure the degree of order in the shortest possible time to test its thermal expansion and contraction caused by chemical changes physical harm.

Application

- Electronic parts

- Home appliance

- Auto parts

- Aviation parts

- LED lights

- Plastics

- Metals

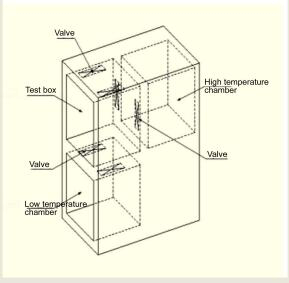

Structure

Detailed pictures

Japan OYO Controller

Germany Bitzer compressor

- Working chamber corrosion resistance SUS#304 stainless steel material

- Japan OYO Programmable LCD controller,program with 120 groups,14400 segments

- Cascade refrigeration system,France “Tecumseh” compressor

- Environment friendly Refrigerant R404A & R23

- Casters for easy moving during installation or relocation

- RS232 computer interface and software

Meet the following standards:

GB/T2423.1-1989

GB/T2423.2-1989

GB/T2423.22-1989

GJB150.5-86

GJB360.7-87

GJB367.2-87

| Model | JYTS-50 | JYTS-80 | JYTS-100 | JYTS-150 | JYTS-250 | ||||||

| Inner Size(W*D*H)cm | 36*40*35 | 50*40*40 | 50*50*40 | 60*50*50 | 70*60*60 | ||||||

| Overall Size(W*D*H)cm | 156*144*175 | 170*144*180 | 180*144*180 | 180*154*190 | 190*164*200 | ||||||

| Preheating Temp.range | ±60℃~±200℃ | ||||||||||

| Precooling Temp.range | -10℃~-70℃ | ||||||||||

| SamplesTest Temp.range | +60℃~+150℃ | ||||||||||

| -10℃~-40℃; -10℃~-55℃; -10℃~-65℃ | |||||||||||

| Performance | Temp uniformity | ±2℃ | |||||||||

| Recovery time | 3-5 min | ||||||||||

| Heating up time | ℃ | 150 | 150 | 150 | 150 | 150 | |||||

| min | 30 | 40 | 40 | 40 | 40 | ||||||

| Cooling down time | ℃ | -55 -65 -75 | -55 -65 -75 | -55 -65 -75 | -55 -65 -75 | -55 -65 -75 | |||||

| min | 70 80 90 | 70 80 90 | 80 90 100 | 90 100 110 | 100 110 120 | ||||||

| Material | Inner Material | Stainless steel plate(SUS304) | |||||||||

| Exterior Material | Stainless steel plate+spray painting | ||||||||||

| Insulation Material | Rapid polyurethane foam and glass wool | ||||||||||

| System | Blower | Centrifugal blower | |||||||||

| Heater | Nickel alloy electric heating wire heater | ||||||||||

| Refrigeration system | Cascade refrigeration system,Tecumseh compressor | ||||||||||

| Controller | Japan OYO9226S LCD Touch Screen Programmable temperature controller | ||||||||||

| Accessories | Two shelves,lead hole 1(optional),recorder(optional) Outlook window (optional) | ||||||||||

| Safety device | No fuse breaker,fuse,compressor over-pressure,overheating,over-current protection,over-temperature protection,water flow protection,phase sequence protection,oil pressure protection,pressure relief protection,low voltage protection | ||||||||||

| Power(kw) | 3 phase AC380V 50HZ/60HZ | ||||||||||

| 20 21 22 | 21 22 23 | 22 23 25 | 28 35 45 | 30 40 50 | |||||||